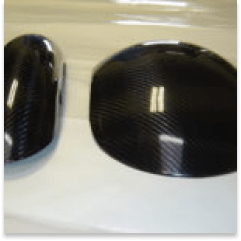

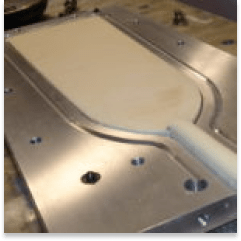

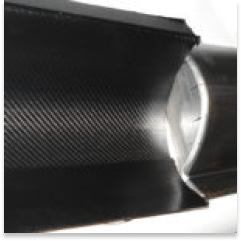

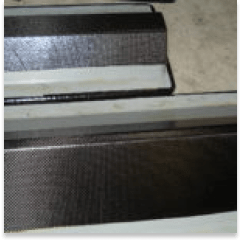

With 250 tons of hydraulic pressure and a maximum temperature control of 900 degrees Fahrenheit, along with water-cooling platens to maintain tight tolerances during heat soak curing, hydraulic hot pressing is sometimes a great option for high-volume manufacturing of carbon fiber or composite parts.

Finishline Advanced Composites also has extensive experience in the world of hydraulic hot presses for the advanced composite industries. Regardless of your process requirements, our vast knowledge and high-quality machinery, equipped with up-to-date software, provide customers with greater press control and flexibility to optimize product quality and process performance.

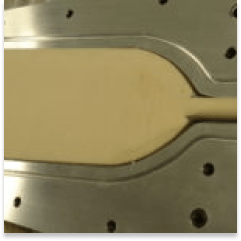

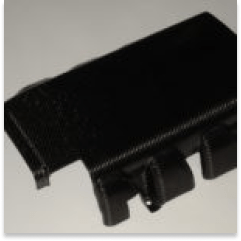

Enhance your product processes for resins, composites, and thermoplastics with our composite molding press solutions. Finishline is eager to learn more about your business and identify any areas where improvement may be needed. Let’s get started and explore our custom capabilities today.

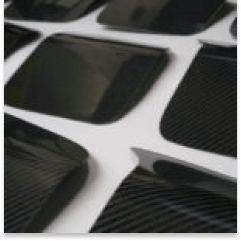

Finishline Composites offers a variety of high-temperature molding press types, including automatic hydraulic press systems for the compression molding of all types of composites and thermoplastics.