Motorsports / Racing

We manufacture carbon fiber/composites for any industry. From design, Custom one-off products, prototyping, small or large scale production projects, we also offer composite repair services.

Read MoreAviation

We manufacture carbon fiber/composites for any industry. From design, Custom one-off products, prototyping, small or large scale production projects, we also offer composite repair services.

Read MoreMedical

We manufacture carbon fiber/composites for any industry. From design, Custom one-off products, prototyping, small or large scale production projects, we also offer composite repair services.

Read MoreMilitary and Defense

We manufacture carbon fiber/composites for any industry. From design, Custom one-off products, prototyping, small or large scale production projects, we also offer composite repair services.

Read MoreAerospace

We manufacture carbon fiber/composites for any industry. From design, Custom one-off products, prototyping, small or large scale production projects, we also offer composite repair services.

Read MoreUAV's / Drones

We manufacture carbon fiber/composites for any industry. From design, Custom one-off products, prototyping, small or large scale production projects, we also offer composite repair services.

Read MoreFINISHLINE ADVANCED COMPOSITES IS A ONE-STOP CARBON FIBER/COMPOSITE SHOP

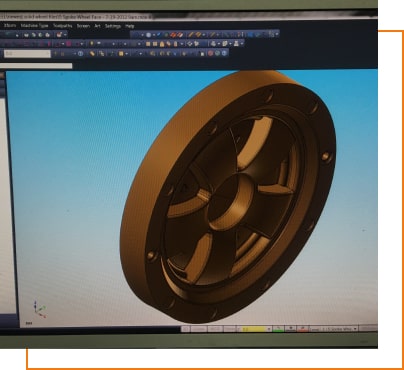

Specializing in Carbon Fiber/Composites. We manufacture custom one-off prototypes to small or large scale production projects. We also offer composite repair services. Here at Finishline we have small to large, state of the art equipment. This allows us to manufacture a small or very large part or parts.We offer a complete line of composite technologies. Finishline creates your idea into reality. (Design, development, prototyping, testing & production). We offer the ability to do simple to complex projects.

About US

25 long years of manufacturing excellence with quality at its best!

At Finishline, we believe that quality and fulfilling the customer’s needs are the key ingredients. With every job, whether it is big or small, simple or complex, it is to be completed with perfection.

Upon graduation with a mechanical engineering degree, I started working at an aerospace composite plant. I performed a number of jobs, the main one being a supervisor

SERVICES

Our customers will always receive top-notch service, and product for a very affordable price.

The only place where you’ll get the perfect solution for all your advanced composite, carbon fiber needs.

BENEFITS OF ADVANCED COMPOSITE MATERIALS

- Composite parts provide superior strength and stiffness while being light weight, and it can be formed into complex shapes. Ideal applications are large complex-shaped structures such. Composites products are widely used in many applications where high performance and great mechanical properties are required such as aerospace, race cars, boating, sporting goods, and industrial applications.

- The wide range of available advanced composite materials and resin system combinations makes it an ideal material to achieve specific performance requirements. As a result, composite materials are replacing metal and plastic in many industries and is the material of choice for many new applications.

- Advanced composite materials are characterized by high specific strength and stiffness and, in combination with automatic manufacturing processes, make it possible to fabricate composite structures with high levels of weight and cost efficiency. The replacement of metal alloys by composite materials, in general........READ MORE

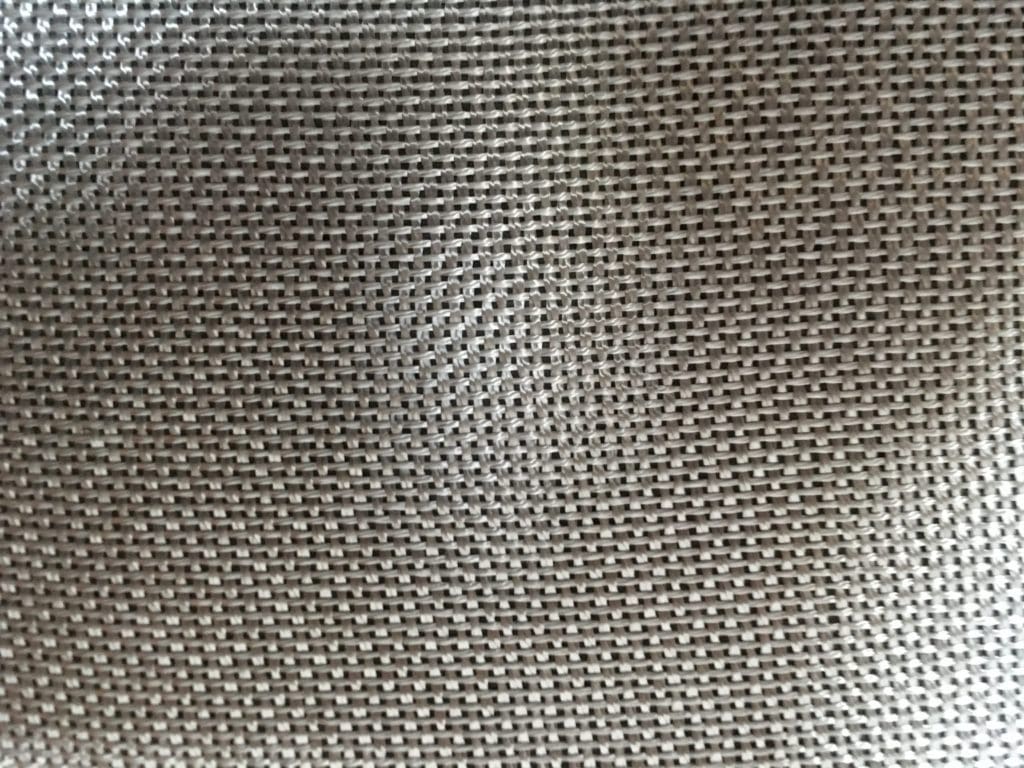

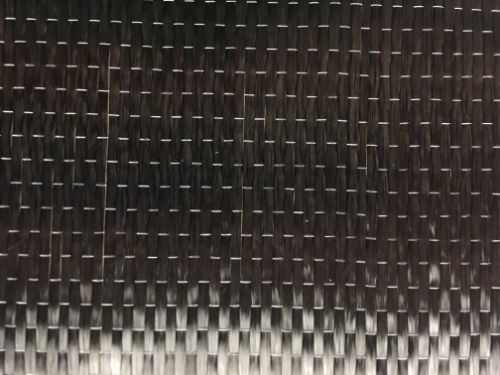

MATERIALS gallery

Gallery of various different types of composite reinforcements that we supply and use