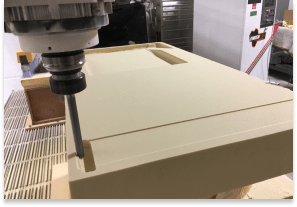

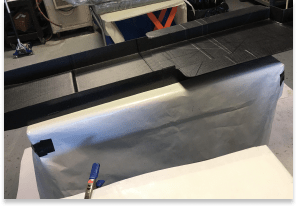

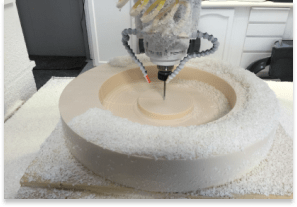

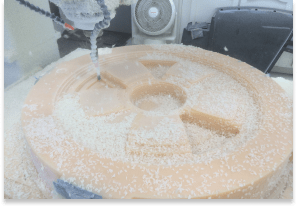

With a massive 5' x 10' working envelope, we have the capability to work on large parts.

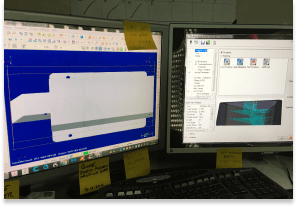

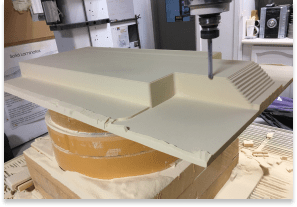

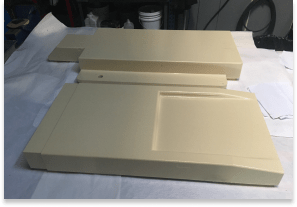

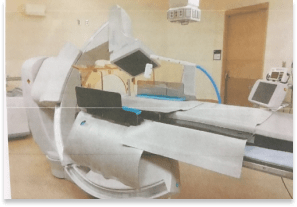

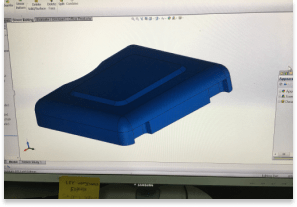

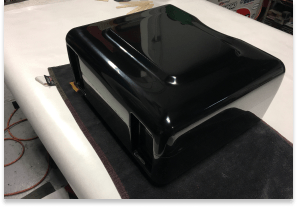

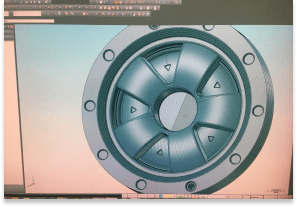

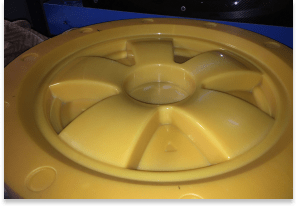

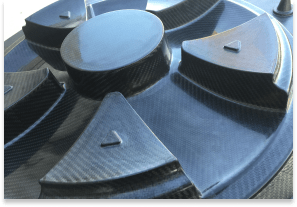

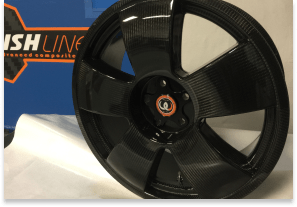

The images on the left depict a brief description of the steps involved in taking a 2D or 3D drawing and transforming it into a master part.

Whether you require highly accurate parts, fully functional engineering prototypes, peace parts, patterns, or molds, FinishLine Composites is committed to working with your specific requirements to find the optimal solutions. Our extensive range of CNC machining platforms encompasses a wide range of sizes and quantities. We offer three-axis and five-axis machining capabilities, working with a variety of metals, plastics, and composites.

At FinishLine Composites, we specialize in machining large parts and models. Our machining centers are capable of producing parts and models measuring up to 5′ x 10′ x 3′.

Furthermore, our high-speed five-axis machine bridges the gap between what can be 3D printed and what should be 3D printed, ensuring precise and efficient manufacturing processes.