Autoclave curing is the most widely used method for producing high-quality composite laminates in the composite industry.

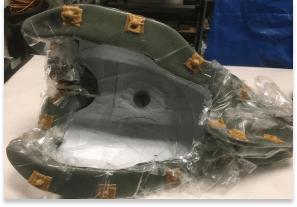

Autoclaves are used in several industries to assist in the manufacturing of polymeric composites. Although the autoclaving process can be applied in various industries, it is commonly utilized in the aviation sector. The following describes one method of curing composites: pre-preg plies are individually arranged in their final configuration inside vacuum-sealed bags, which are then subjected to external pressure while maintaining internal vacuum. This process ensures the creation of a single composite layer that is uniform in quality and structure. In the case of thermoset pre-pregs, high temperatures are employed during both the initial and final stages of the autoclaving process. The pressure and temperature in these machines are controlled separately, thereby functioning independently of each other.

The autoclaving process allows manufacturers and their customers to produce materials of the highest quality. Autoclaves utilize heat and pressure to enhance a variety of products, thereby improving their overall quality and strength. As a result, the machines and aircraft used in the aviation industry are capable of withstanding demanding environments. Autoclave manufacturers play a crucial role in producing composite autoclaves that can manufacture high-quality products.