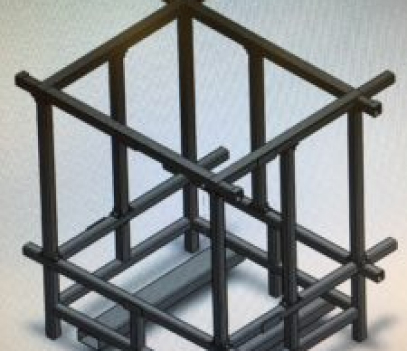

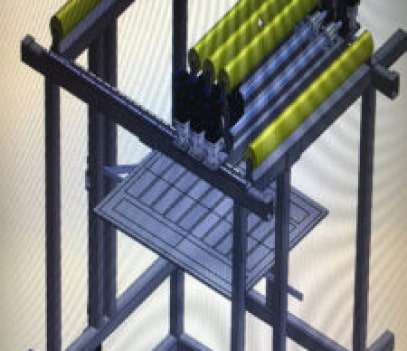

FinishLine’s newest piece of equipment is a carbon fiber, composite custom-built, large-format, high-temperature FDM 3D printer designed to specifications. From prototyping to large scale production runs, it proudly holds the title of being the largest advanced composite printer of its kind in the world, and it took precisely 4 years to complete from start to finish.

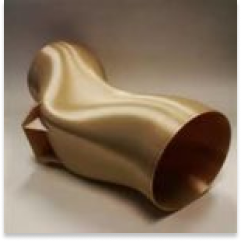

The Prometheus 3D printer is purpose-built for design, prototyping, manufacturing and producing 3-D Prints in a wide variety of printing mediums. Whether printing Master parts/Bucks for manufacturing carbon fiber/composite prepreg molds/tools or high-temp. molds/tools printed out of Ultem 1010 capable of Autoclave processing. Where precision and durability are essential. It excels in both small and large-scale production environments. With the largest building envelope size among FDM 3D systems and capable of printing temperatures high enough to successfully print Peek. It is designed to handle the most demanding manufacturing needs. The Prometheus 3D printer is compatible with a wide range of filament mediums, including PLA, ABS, ASA, Polycarbonate, Nylon 12, Utem 1010, Ultem 9085, Peek, and more.

Here at Finishline Advanced Composites we provide the highest level of fabrication, welding, assembly, finishing, painting, 3-D printing, CNC machining, and scanning. Our high precision measurement equipment and specialized machinery, equipment enables us to meet to the highest standards of quality, tight tolerances, and competitive lead times. At Finishline Advanced Composites, our advanced composite prototype group is staffed by experienced engineers and seasoned composite craftsmen.

Advanced composite prototyping can encompass a wide range, from simple test parts to fully functional production-ready assemblies. Frequently, individual components and sub-assemblies undergo rigorous testing to verify design parameters and ensure that the final product meets all the required specifications.

FinishLine Composites is an experienced team of industrial designers and engineers who deploy cutting-edge additive manufacturing technologies to assist our clients every step of the way. Whether we are working with existing files, helping you design your product from the beginning, or making suggestions to reduce production costs, we are well-versed in CAD and CAM software programs.

If you have any questions or require further assistance, please do not hesitate to contact us. (707)673-2637